About us

Kovoflex spol. s r.o. was established in 1995. The owner of the company has been engaged in the production of engineering components since 1989. The company’s profile was pressing and welding of metal components. At that time the company started it´s activity in a rented building of about 600 m² in Štvrtok na Ostrove with 15 employees. After two years from the establishment, the production started to expand with the relocation of the operation to Veľké Blahovo.

- 1997 Rozšírenie sa začalo na 22 000 m² pozemku, vznikli nové priestory s rozlohou 1000 m². Firma svoju výrobu rozširoval s kovoobrábaním a montážou vlastnej výroby.

- 2000 Z dôvodu neustáleho rastu výroby firma investovala do vybudovanie novej 600 m² haly na skladovanie výrobkov a rozšírenia výrobnej haly o ďalších 600 m².

- 2002 Vznikla nová samostatná 800 m² hala pre zváračských a farbiacich prác.

- 2003 Ďalej sa investovalo do rozšírenia výrobných strojov ako robotické zváranie, NC obrábací stroj, delenie a rezanie s plazmou a plameňom.

- 2006 Výrazné rozšírenie administratívnych priestorov, montážnej haly a skladu v celkovom výmere 3500 m² ako aj zakúpenie nového lasera na spracovanie materiálu.

- 2008 Zakúpenie CNC frézovacieho centra.

- 2009 Zakúpenie CNC sústruhu.

- 2010 Zakúpenie nového lasera kvôli zefektívňovaniu výroby

- 2013 Vybudovanie novej haly na účely nástrojárne a trieskového obrábania kovov – kompletné vybudovanie s modernými technológiami

- 2015 Rozsiahla modernizácia strojového parku – zakúpenie viacosového CNC sústruhu, 4 metrového ohraňovacieho lisu

- 2017 Ďalšia modernizácia – zakúpenie nového tabuľového a rúrkového laseru

- 2020 Zakúpenie 3D meracieho prístoja

History of the company

1995 – The company was established.

2000 – Due to the continuous growth of production, the company invested in the construction of a new 600 m² warehouse for the storage of products and the expansion of the production hall by another 600 m².

1997 – Expansion started on 22 000 m² of land, new premises of 1 000 m² were created. The company expanded it´s production with metalworking and assembly of it´s own production.

2001– The production of coupling heads started.

2002 – A new separate 800 m² hall for welding and painting work was built.

2006 – Significant expansion of the administration area, assembly hall and warehouse, total of 3 500 m², as well as the purchase of a new laser for material processing.

2008 – Purchase of a CNC milling centre.

2003 – Further expansion of production machinery such as robotic welding, NC machine tool and cutting with plasma or flame.

- 2006 – The 1 000 000th coupling head has been sold.

1995 – The company was established.

1997 – Expansion started on 22 000 m² of land, new premises of 1 000 m² were created. The company expanded its production with metalworking and assembly of its own production.

2000 – Due to the continuous growth of production, the company invested in the construction of a new 600 m² warehouse for the storage of products and the expansion of the production hall by another 600 m².

2001– The production of coupling heads started.

2002 – A new separate 800 m² hall for welding and painting work was built.

2003 – Further expansion of production machinery such as robotic welding, NC machine tool, and cutting with plasma and flame.

2006 – Significant expansion of the administration area, assembly hall and warehouse, total of 3 500 m², as well as the purchase of a new laser for material processing.

- 2006 – The 1 000 000th coupling head has been sold.

2008 – Purchase of a CNC milling centre.

- 2009 – The 2 000 000th coupling head has been sold.

- 2012 – The 3 000 000th coupling head has been sold.

2009 – Purchase of a CNC lathe.

2010 – Purchase of a new laser for more efficient production.

2013 – Construction of a new hall for the purpose of tool and machining of metals – complete construction with modern technologies.

2009 – Purchase of a CNC lathe.

- 2009 - The 2 000 000th coupling head has been sold.

2010 – Purchase of a new laser for more efficient production.

- 2012 – The 3 000 000th coupling head has been sold.

2013 – Construction of a new hall for the purpose of tool and machining of metals – complete construction with modern technologies.

- 2014 – The 4 000 000th coupling head has been sold.

- 2016 – The 5 000 000th coupling head has been sold.

2018 – Optimization of flaming technology – construction of liquid gas storage tanks.

2015 – Extensive modernisation of the machinery – purchase of a multi-axis CNC lathe, a 4 metre bending press.

2017 – Further modernisation – purchase of new sheet and tube laser.

- 2014 – The 4 000 000th coupling head has been sold.

2015 – Extensive modernisation of the machinery – purchase of a multi-axis CNC lathe, a 4 metre bending press.

- 2016 – The 5 000 000th coupling head has been sold.

2017 – Further modernisation – purchase of new sheet and tube laser.

2018 – Optimization of flaming technology – construction of liquid gas storage tanks.

- 2020 –The 7 000 000th coupling head has been sold.

2021 – Automatization the riveting of coupling heads with CNC riveting equipment.

- 2018 – The 6 000 000th coupling head has been sold.

2021 – Purchase of 3D measuring machine.

- 2022 – The 8 000 000th coupling head has been sold.

- 2018 – The 6 000 000th coupling head has been sold.

- 2020 – The 7 000 000th coupling head has been sold.

2021 – Purchase of 3D measuring machine.

2021 – Automatization the riveting of coupling heads with CNC riveting equipment.

- 2022 – The 8 000 000th coupling head has been sold.

The current number of employees of the company is about 170.

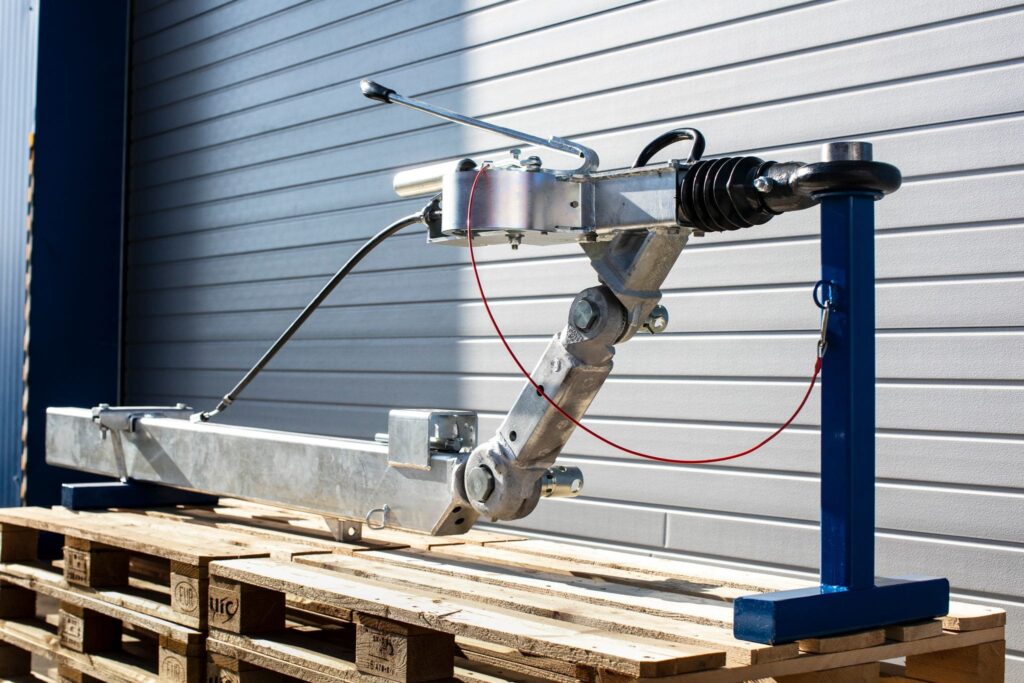

More than 25 years of successful existence of Kovoflex spol. s r.o. testifies to the quality of our products and the precise work of the entire team. The subject of business is metal production – production of parts for trailers. Our product portfolio includes coupling heads, winches, hand brake levers, propstands, highly adjustable drawbars and chassis.

The current number of employees of the company is about 170.

More than 25 years of successful existence of Kovoflex spol. s r.o. testifies to the quality of our products and the precise work of the entire team. The subject of business is metal production – production of parts for trailers. Our product portfolio includes coupling heads, winches, hand brake levers, propstands, highly adjustable drawbars and chassis.

Our production portfolio also includes special projects – special products, customer-specific equipment.

The expansion of technological equipment such as laser cutting, CNC bending, pressing, welding, metal fabrication, sandblasting and painting also provides a competitive advantage. Our products are marketed already after surface treatment.

Kovoflex spol. s r.o. is the primary supplier of the KNOTT group. KNOTT brand is internationally recognized, it is a guarantee of quality. We operate on the EU market, outside the EU and we are also oriented on the US market.

Our products meet the criteria of the strictest European standards. The company operates with a certified quality management system in accordance with STN EN ISO 9001:2016. Our company regularly updates the system of standards to ensure that the quality of products meets the requirements of the European market. Excellent quality of products and professionalism of work has allowed our products to enter the market in several European countries.